ENGINEERING THE FUTURE: Flexible, accurate & reliable high precision grinding solutions

Known worldwide for leading-edge automotive camshaft and crankshaft processing systems, Fives is also a leader in centerless grinding and single & double disc grinding as well as lean and flexible CNC grinders for a wide range of shaft-type components for various industries. With a strong heritage based on the legacy names – Bryant, Cincinnati, Cranfield Precision, Daisho, Gardner, Giustina, and Landis, Fives offers a complete range of grinding machines, plus a comprehensive line of systems, grinding accessories and GrinderCare service program for lifecycle support.

Cincinnati grinding machines are able to accommodate through-feed or in-feed grinding. The high stiffness of our machines ensure optimum accuracy, with fast production rates and high stock removal.

Our range of Landis cylindrical grinding machines provide accurate, reliable, flexible and productive solutions for small, medium and large cylindrical components.

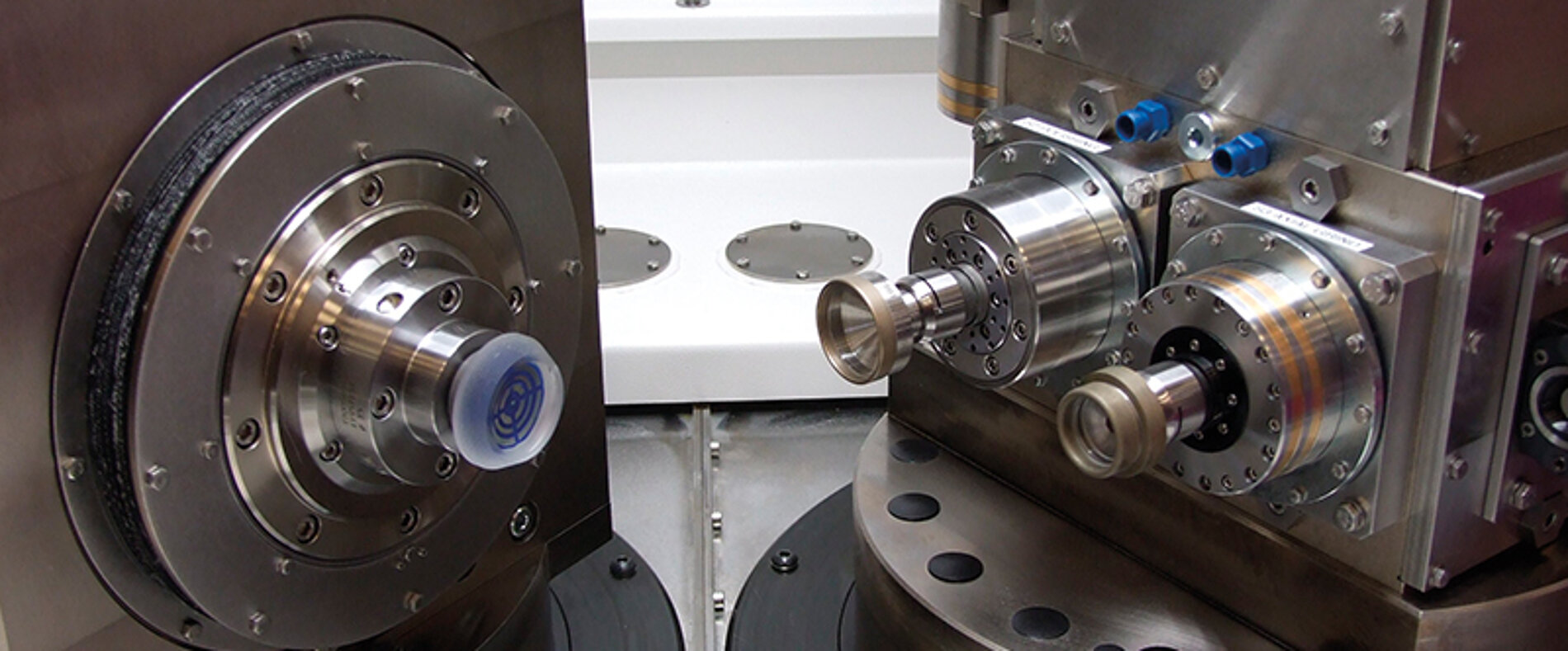

Our Bryant line includes dedicated ID, OD and combination ID/OD (OD/ID/raceway/face) grinders. These grinders are suitable for many applications and come in a range of sizes.

ORBITAL GRINDING

Our range of Landis orbital grinding solutions provide optimized grinding of crankshaft pins and journals and camshaft lobes and journals to non-concentric components.

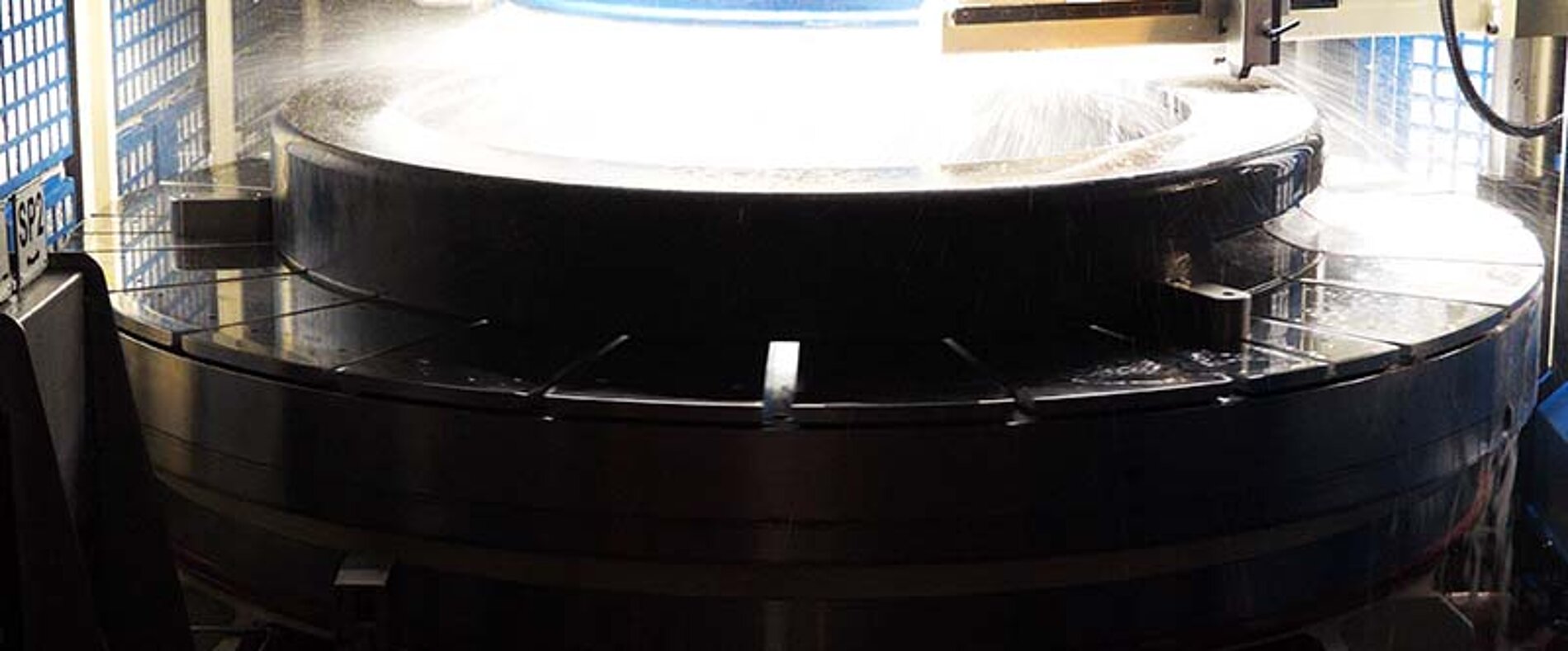

SINGLE & DOUBLE DISC GRINDING

Choose from horizontal double disc grinders, vertical double disc grinders or one of our single disc grinding solutions. Gardner, Giustina or Daisho grinding machines will be proposed according to the standards in your specific geographical area.

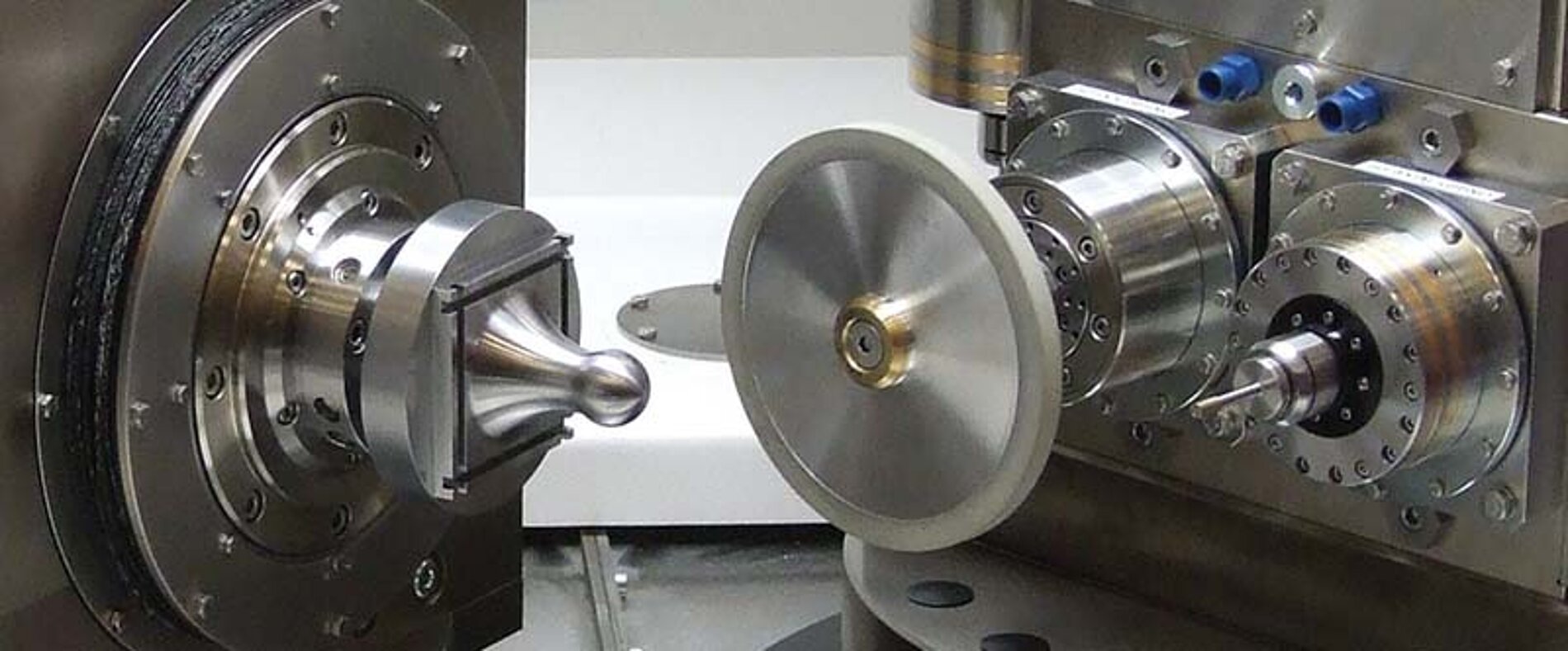

ULTRA PRECISION MACHINING

Cranfield Precision machines range from small optical freeform, prismatic & aspheric grinding to freeform grinding of large optic components to diamond turning for large drumroll.

Subscribe to our Newsletter

Join our quarterly newsletter to receive exclusive updates from the Grinding | Ultra Precision team on our latest news, events and technologies.

GrinderCare

GrinderCare offers complete life cycle solutions for grinding machines around the globe. We offer a full range of services aimed to maximize performance - ensuring your grinding machine will continue to enhance your bottom line year after year. Supported OEM's include:

Besly - Bryant - Cincinnati - Gardner - Giustina - Gold Crown - Landis - Norton - Pratt & Whitney - Warner Swasey

From May 14 to 17, Fives will be exhibiting at GrindingHub, Stuttgart, Germany, in hall 9, booth B31.

Fives is proud to announce a significant order for multiple Giustina Vertical Double Disc Machines for coated brake disc surface grinding.

On July 6, Fives Giustina enthusiastically celebrated its 100th anniversary at its premises in Turin, Italy. Let’s have a look back on an event full of emotion, highlighting human adventure, history…